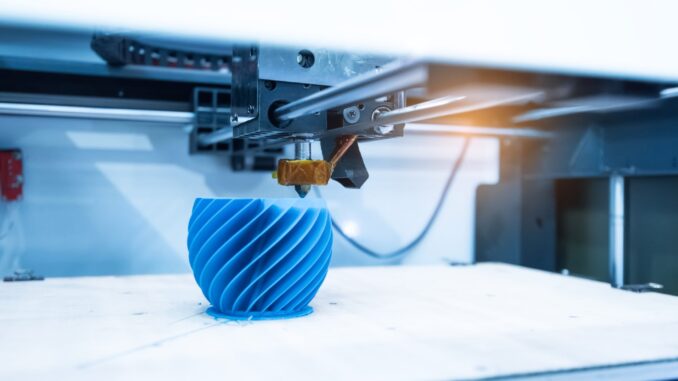

Additive manufacturing (AM), commonly known as 3D printing, has revolutionized various industries

by providing innovative solutions and enabling the creation of complex, customized, and efficient products.

Here are some key applications of additive manufacturing across different sectors:

1. Aerospace

Lightweight Components: AM allows for the design and production of lightweight structures with complex geometries, reducing aircraft weight and improving fuel efficiency.

Prototyping: Rapid prototyping of parts and components for design validation and functional testing.

Tooling: Custom jigs, fixtures, and tooling components that are faster and cheaper to produce.

2. Automotive

Prototyping: Rapid creation of prototype parts for design and functional testing.

Custom Parts: Manufacturing custom and replacement parts, especially for vintage or specialized vehicles.

Tooling and Fixtures: Quick production of custom tools and fixtures for manufacturing processes.

3. Healthcare

Medical Implants: Custom orthopedic implants tailored to the patient’s anatomy, such as hip and knee replacements.

Prosthetics: Personalized prosthetic limbs that fit better and provide improved comfort and functionality.

Dental Applications: Custom dental implants, crowns, bridges, and orthodontic devices.

4. Consumer Goods

Customization: Personalized products such as eyewear, footwear, jewelry, and home décor items.

Rapid Prototyping: Quick development and testing of new product designs.

Fashion: Innovative fashion items including clothing, accessories, and even footwear with complex designs.

5. Education and Research

Learning Tools: Educational aids and models for teaching complex concepts in fields like biology, chemistry, and engineering.

Research Prototypes: Creation of prototypes for research projects and experimental purposes.

6. Architecture and Construction

Architectural Models: Detailed scale models of buildings and structures for visualization and planning.

Construction: Printing components for buildings, including walls and structural elements, potentially reducing construction time and costs.

Interior Design: Custom furniture, fixtures, and decorative elements.

7. Electronics

Custom Enclosures: Tailored enclosures for electronic devices and prototypes.

Circuit Boards: Experimental 3D printing of circuit boards and electronic components.

8. Medical and Surgical

Surgical Models: Patient-specific anatomical models for pre-surgical planning and simulation.

Bioprinting: Research into printing tissues and organs for transplantation and medical research.

Drug Delivery: Customized drug delivery devices and pills with complex release profiles.

9. Food Industry

Custom Food Items: Creating intricate and personalized food items, such as chocolates and decorative pieces.

Nutritionally Customized Foods: Development of foods tailored to individual dietary needs.

10. Art and Design

Artistic Creations: Unique sculptures and art pieces that leverage the design freedom of AM.

Design Prototypes: Rapid creation of prototypes for evaluation and iteration in the design process.

11. Defense and Military

On-Demand Parts: Production of replacement parts in remote locations or in the field.

Customized Equipment: Development of specialized equipment and gear tailored to specific mission requirements.

12. Energy

Wind Turbine Components: Production of complex and optimized components for wind turbines.

Oil and Gas: Custom parts and tools for exploration and extraction processes.

13. Fashion and Jewelry

Complex Designs: Creation of intricate and customized jewelry designs that are difficult to achieve with traditional methods.

Rapid Prototyping: Fast development and testing of new fashion accessories.

The versatility and potential of additive manufacturing continue to expand as the technology advances, opening up new possibilities and applications across various fields.

Leave a Reply